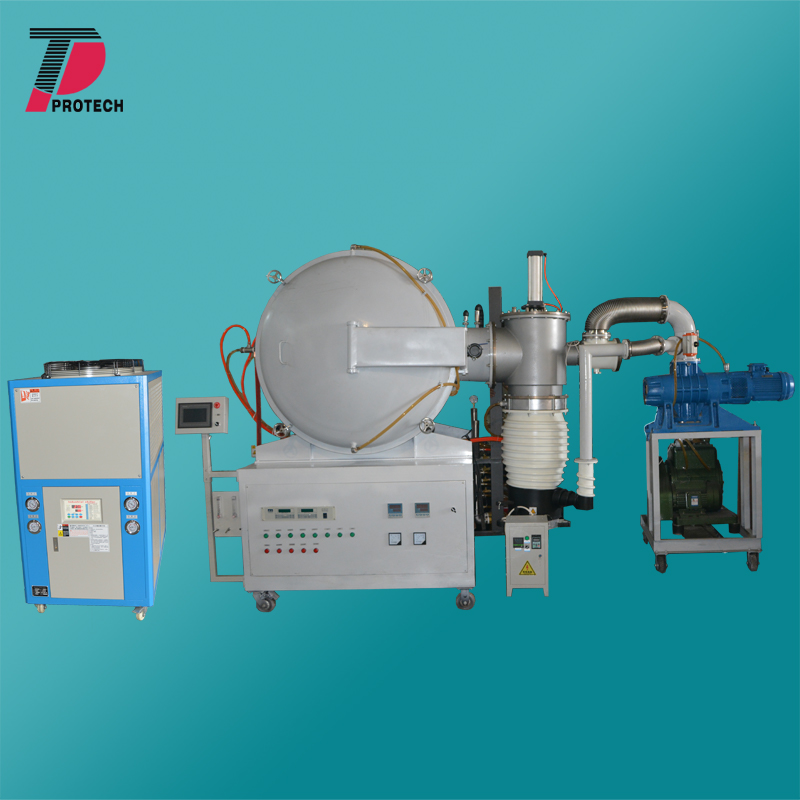

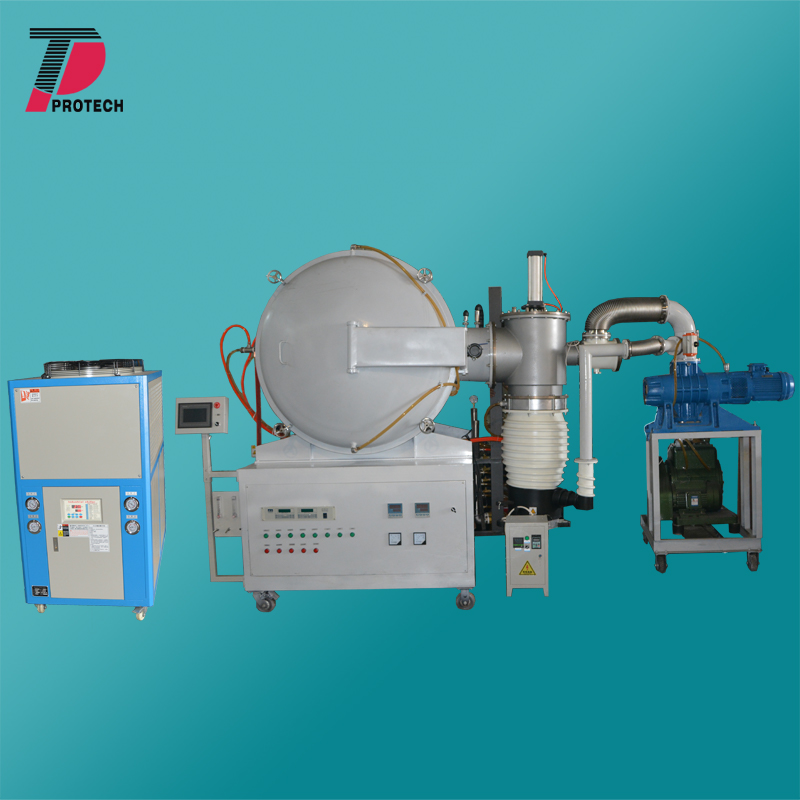

model:PT-1500

High temperature vacuum brazing furnace

Application: It is used in high-temperature brazing, sintering, tempering, annealing and other processes of stainless steel, copper, titanium alloy, cemented carbide, high-temperature alloy and other materials.

Contace us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Product overview:

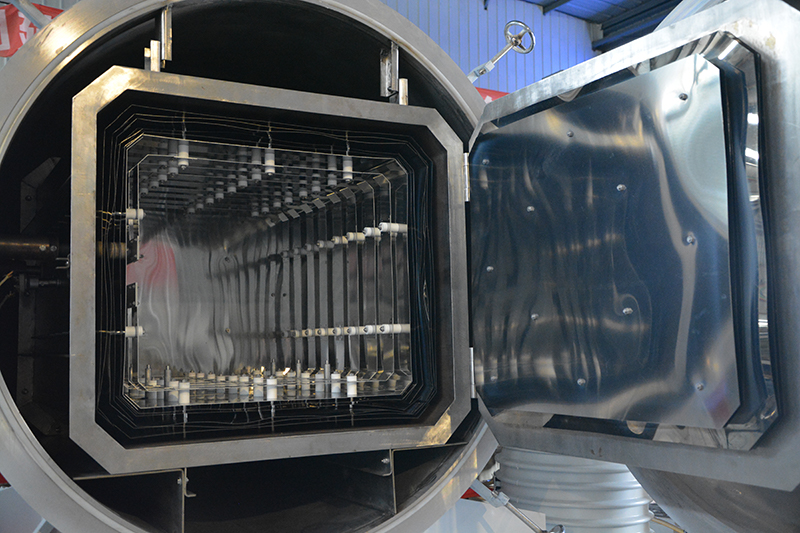

vacuum brazing furnace is a complete set of equipment for high-temperature heat treatment under vacuum (or other atmosphere) conditions. The metal liner is made of high-temperature resistant stainless steel (heat shield function), molybdenum belt as heating element, and double-layer water cooling The vacuum chamber can be equipped with a circulating water refrigeration system to cool the furnace body. This equipment combines vacuum/atmosphere and high-temperature heating, and is used in high-temperature brazing, sintering, tempering, annealing and other processes of stainless steel, copper, titanium alloy, cemented carbide, high-temperature alloy and other materials.

Product composition:

Vacuum brazing furnace is mainly composed of furnace body, furnace cover, heating and heat preservation system, vacuum system, gas filling device, water cooling system, control system, etc.

Technical parameters:

Equipment form: Periodic operation

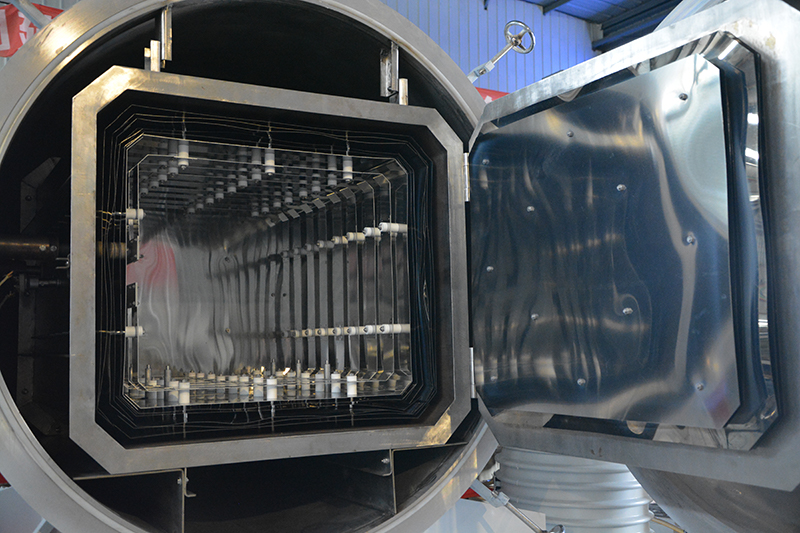

Heating form: Molybdenum belt heating element

Furnace material: Metal heat shield

Heating power: <60KW (subject to actual power)

Power supply voltage: 380V, three-phase, 50Hz

Working size: 500×400x400mm (Length x Width x Height)

Maximum temperature: 1500°C

Rated temperature: 1200°C

Protective atmosphere: Argon or high purity nitrogen

Backing pump: 2X-70 mechanical rotary vane pump

Roots pump: ZJP-300 Roots pump

High vacuum pump: TK-400 diffusion pump

Ultimate vacuum: 6.67×10-3Pa (empty furnace, cold state, purified)

Vacuum gauge: Digital display compound vacuum gauge

Constant temperature accuracy: ±1°C

Monitoring thermocouple: It is possible to install a monitoring thermocouple. Monitoring the temperature in the furnace

This product has horizontal and vertical structures, and the furnace type can be customized according to user needs, and various non-standard vacuum brazing furnaces and vacuum sintering furnaces can also be customized according to user needs.